What Is A Spin Coater?

A: A machine used for spin coating is called a Spin Coater.

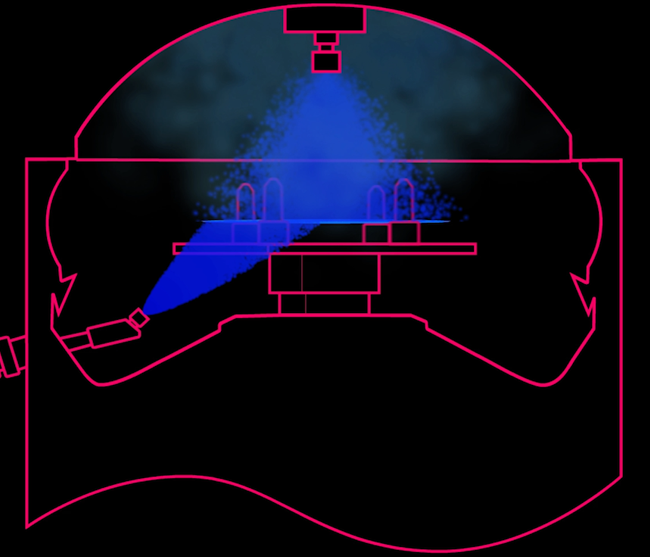

A Spin Coater is a device used to apply a film to a substrate. The system will rotate a substrate at various speeds while coating material is dispensed onto its surface. Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved.

Spin coaters are used in the process of Spin Coating.

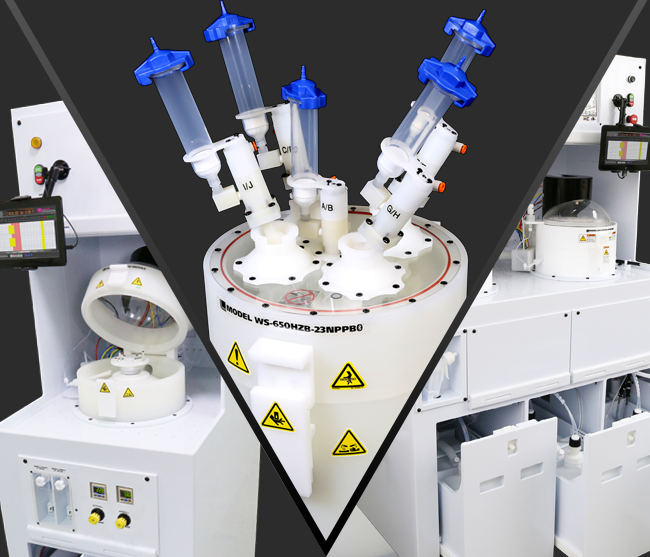

What Makes a Laurell Spin Coater?

Making the most popular single wafer spin coater in the world requires innovation, and attention to detail.

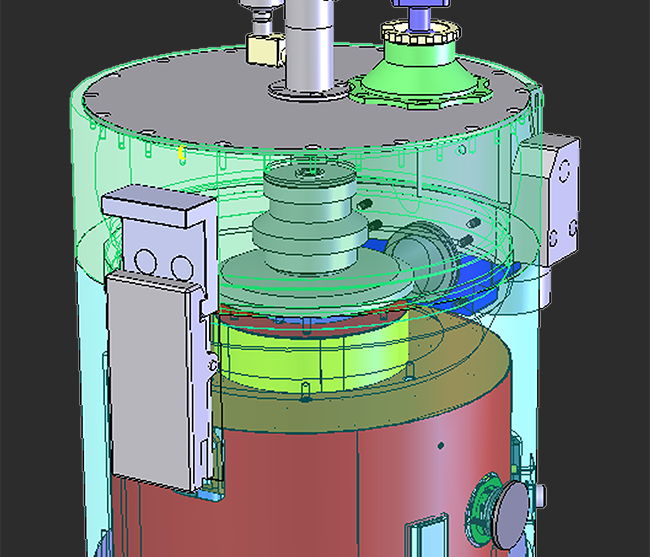

The Right Materials

A seamless housing machined from chemically resistant copolymer allows one system to be used with many processes. Zero porosity flouropolymer housings are available for the most severe chemistry.

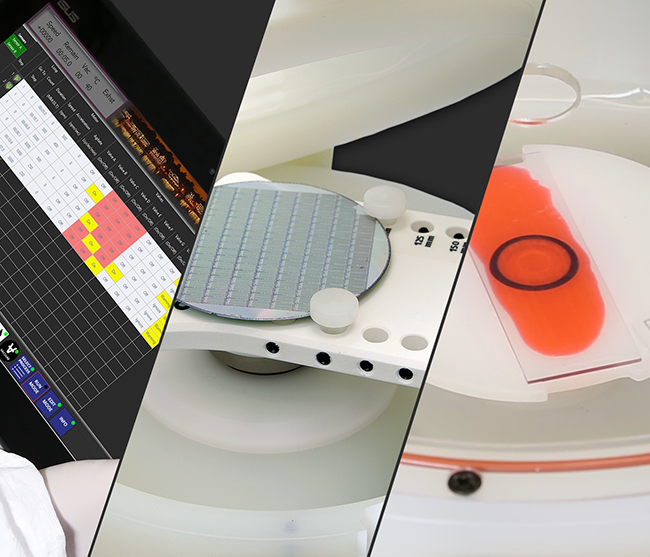

Ease of Use

Laurell spin coaters have been designed to make it easier to get your best results. Programming and control are simple, loading and unloading your substrates is easy, and the right chuck for your substrate is available.

Safety

Safety is built-in to every Laurell spin coater. Your physical security is protected by an impact tested housing, software and physical interlocks prevent opening a rotating system and starting a program while the process chamber is open.

Performance

Up to 13,000 RPM top speed, up to 30,000 RPM/Second acceleration. Laurell Technologies has high performance motors that can spin larger, heavier substrates.

Process Focused

Laurell Technologies support and sales staff have years of experience working with coating and aqueous processing in industrial and R&D environments. This experience informs all our design and engineering decisions and ensures that we focus on making sure your process is successful.

Custom Solutions

Our customers are exceptionally inventive and we have worked together with many groups to bring an original idea into reality. Custom solutions require a collaborative approach and Laurell Technologies is ready to listen to your unique spin coating proposal.